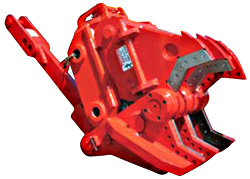

RE-BAR SHEAR

RE-BAR SHEAR

APPLICATIONS

Concrete Recycling: Increase the value of re-bar by-product using existing excavators. Increase machine utilisation and maximize profit.

Demolition Contractors: Maximize profit and machine utilization on large concrete demolition jobs. Time taken to density re-bar into balls, could shear it down to a profitable dense size.

Scrap Salvage: Perfect for cutting large bundles of tangled re-bar quickly and safely. Saves wear and tear on hydraulic shears and shredder.

ADVANTAGES

Value and Speed: The Re-bar Shear is the preferred tool for many demolition contractors, concrete recyclers, and scrap processors for cutting tangled re-bar. It has superior speed at 30-36 cuts per minute, and is a fraction of the cost of comparable hydraulic units. Bucket linkage design is inexpensive to purchase, install and maintain.

Rigid and Durable: Thick, high-tensile jaw material and extra jaw stiffeners ensure zero jaw flex for ultra-tight blade tolerance. Thicker high tensile steel for fabrication and factory hard facing give greater durability. Opposing shear faces are incorporated to balance the sequential cutting cycle.

Re-bar Shear turns tangled re-bar into profitable scrap. Patented sequenced cutting action allows for three cuts per cycle and maximum productivity.

Profitable: Creates dense processed scrap from low-value waste material. A 40 ton 188,000lb] excavator can process 6-8 tons per hour of tangled re-bar, reducing it to pieces with an average size of one foot. Our studies show the break-even point for this product occurs at 150 - 200 hours of operation.

Simple Maintenance: The shear utilises 12 identical blades, each with four usable edges. Maximum utilisation means less consumables. Threaded shear blades allow for easy shimming and replacement.

Extra Heavy Duty Pivot Group: Oversize high tensile shaft, case hardened with a 360 degrees lubricating grease system and fitted with semi-self lubricating bushes. Two-into-three pivot provides greater jaw rigidity.

RMS 300 for excavators 65,000 - 100,000 lbs.

RMS 400 for excavators 85,000 - 110,000 lbs.

RMS 650 for excavators 110,000 - 150,000 lbs.

|

MODEL |

WEIGHT |

JAW OPENING |

CUTTING WIDTH |

CUT LENGTH BTW JAWS |

JAW CUT LENGTH |

|

RMS 300 |

5,000lb / 2,300kg |

18” / 450mm |

16” / 410mm |

16” / 410mm |

14” / 350mm |

|

RMS 400 |

6,820lb / 3,100kg |

22.4” / 460mm |

22.4” / 570mm |

11” / 280mm |

15.7” / 280mm |

|

RMS 650 |

10,560lb / 4,800kg |

24.8” / 630mm |

24” / 610mm |

12” / 410mm |

19.7” / 500mm |

© The St. George Company Ltd. | Toll Free 800-461-4299 | Phone 519-442-2046 | Fax 519-442-7191

TERMS & CONDITIONS

WARRANTY & DISCLAIMER

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11